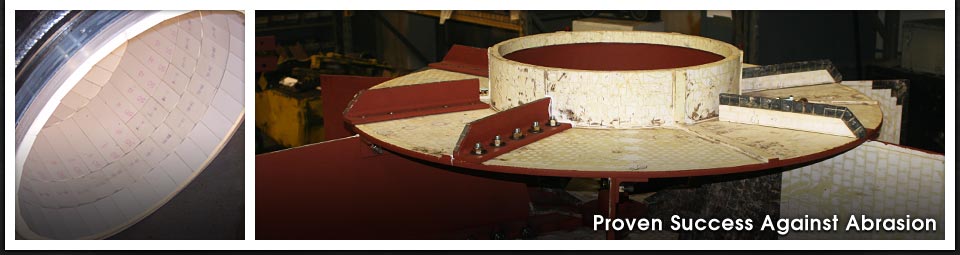

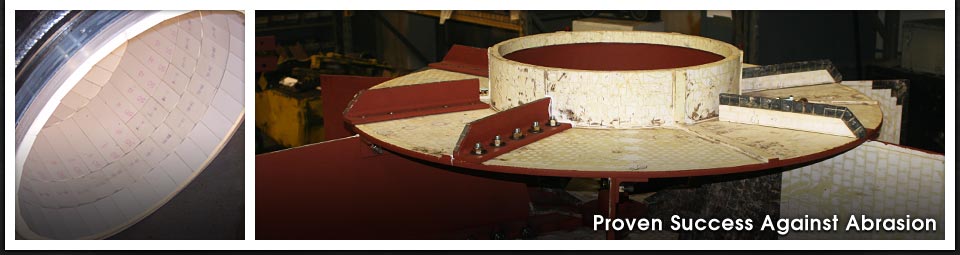

WEAR SOLUTIONS // WEAR MATERIALS

- High Alumina Ceramic

- Silicon Carbide

- Tungsten Carbide

- Boron Carbide

- Specially Engineered Carbides and Oxides

- UHMW, Rubber, Urethane

- Trowelable Ceramic/Carbide Compounds

- Domite

- Weld and dual wire spray overlays of new and pre-fabricated components for service in corrosive, erosive, high temperature (up to 2000 F working temperature) and high impact environments.

- Hard/Wear surfacing using nickel chrome, nickel chrome boron, chrome carbide, tungsten carbide or chrome cobalt.

- Weld and Wire Spray Overlays: Overlays can be applied to any base material of weldable quality. Carbon Steel, Chrome Moly, Low Alloy Steel, Stainless Steels, Inconels, Monel, NiHard, Castings.

- Typical overlays are: Chromium Carbide Boron, Chromium Cobalt (Stellite), Fused Tungsten Carbide/Nickel Chromium, Fused Tungsten Carbide/Vanadium Carbide, AshX, WearX, 300 - 400 Series S.S., 904L Duples Stainless, 2205, 2507 Hastelloy C-276, 686 CPT, Alloy 400, 600, 625, 800, Copper Nickel, Aluminum Bronze.

|

|

|